Energy Independence Starts Here

Electricity prices are on the rise. This system allows you to produce your own electricity at low cost burning wood and other biomass materials. These systems can also be attached to your vehicle or tractor reducing your reliance on gasoline.

We are now selling gasification units with 5-20kw generators ready to produce power 24 hours a day, 7 days a week. We also custom build units to fit almost any gasoline engine up to 120hp. We can equip your unit with smart controls for automatic feeding and material agitation.

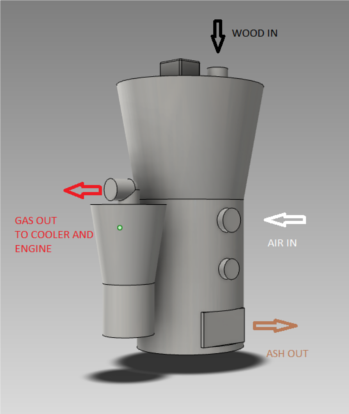

The basic operation of the gasifier is to burn everything that is not carbon dioxide and hydrogen out of the wood, this creates a flammable gas that replaces gasoline in an engine. There are scrubbers and filters built into the unit that further separate water and tar, these are redundant systems to insure against possible fluctuation in the fire chamber (reactor). We can automate the feed stock so you only have to handle material at 1-6 month intervals. gasification units start at $3200 for 5-20 hp. and go to $4200 for a 120 hp.

- Downdraft gasification design, compact structure, high efficiency, and simple operation.

- There is no need to shut down to add more fuel, ensuring consistent operation for the user.

- Gas is very clean, thanks to an innovative filtration system

- The entire unit occupies 4 feet by 8 feet of space.

- Maintenance and fueling takes only 10 minutes per day.

- Can be fueled with biomass or gasoline.

- Will deliver to Minnesota, Wisconsin, and Colorado.

Call or e-mail

Telephone: 218-849-2264

E-mail: ryanjlehto@gmail.com